Safety Stock Is Not Necessary In Any Fixed-time-period System

Safety stock is not necessary in any fixed-time-period system. Even relatively large fluctuations in demand can be. Safety stock is not necessary in any fixed-time-period. We need to maintain the extra stock to ensure a consistent flow of business and retain our customers.

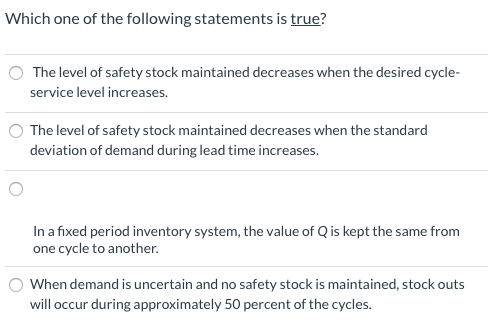

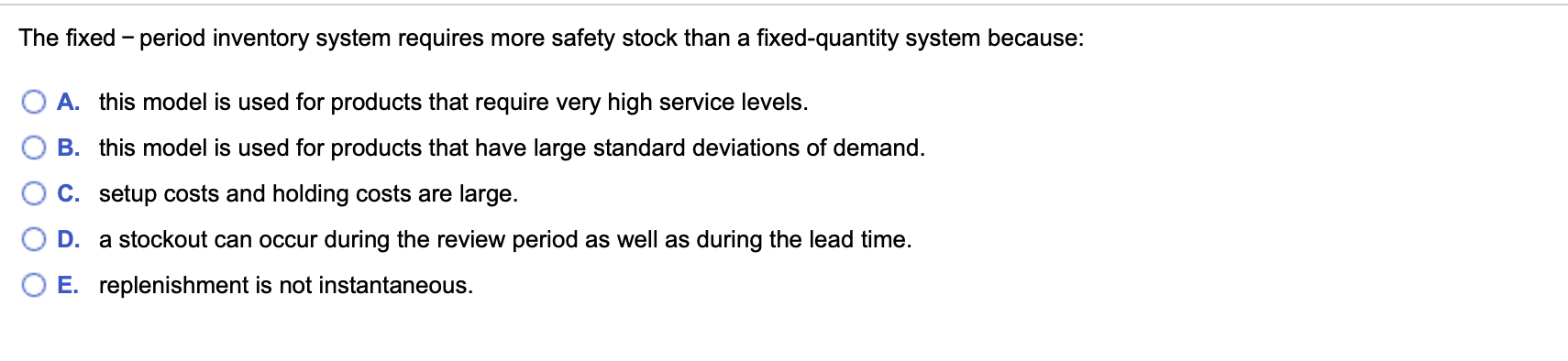

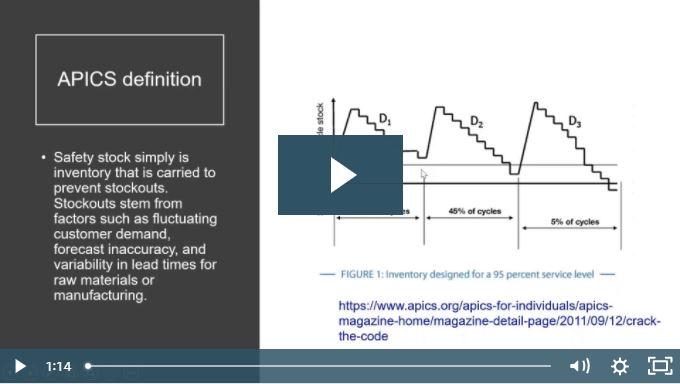

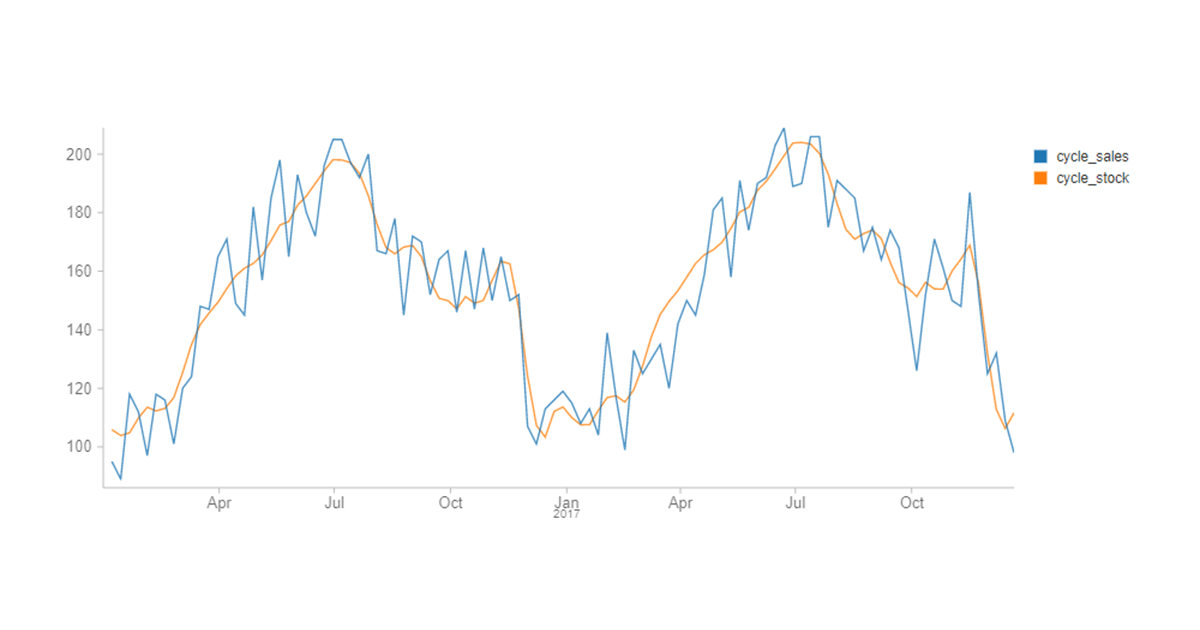

Stock-outs or the moment that your product is out of stock present a 1 trillion problem. For another 45 percent of cycles the safety stock will suffice. These generally require a higher level of safety stock than a fixed-order-quantity system.

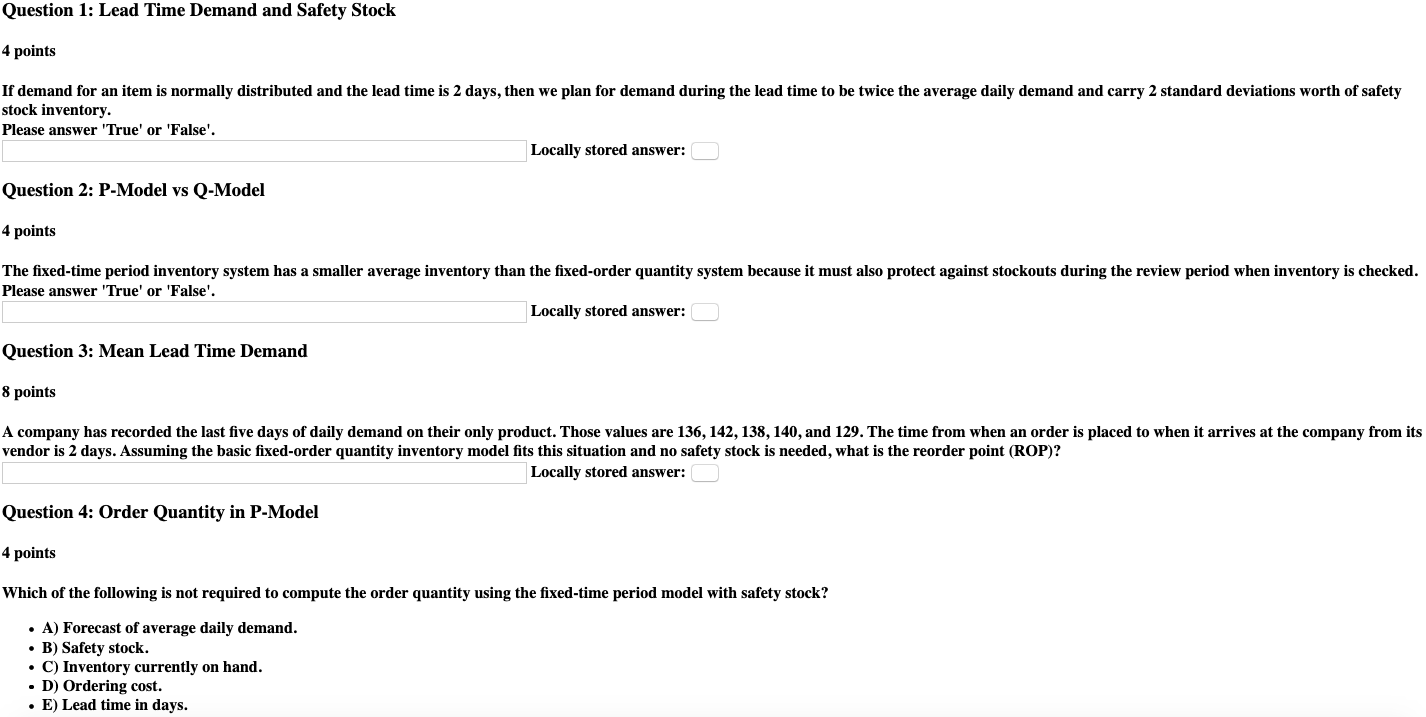

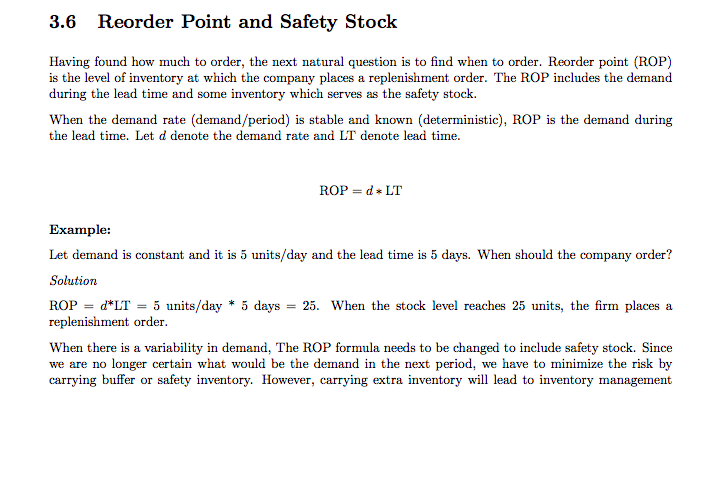

There have been a number of simulation studies of MRP systems Whybark and Williams 1976 Grasso and. Safety stock is not necessary in any fixed-time period system. LT Time Maximum probable demand during lead time Expected demand during lead time ROP Quantity Safety stock Du UNB SCM 30 83.

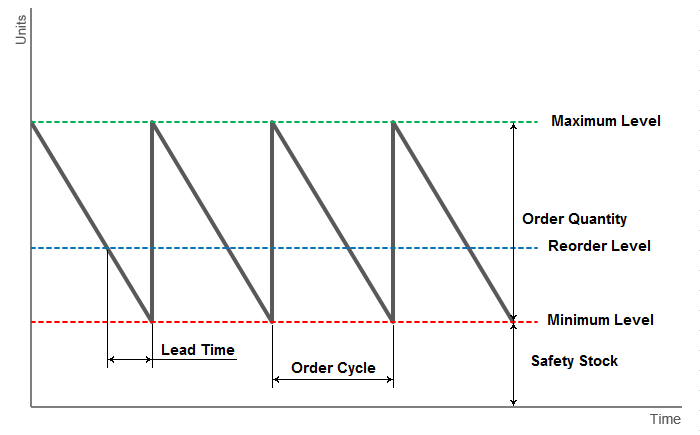

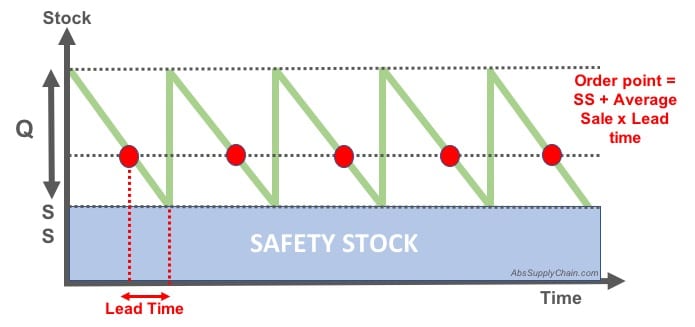

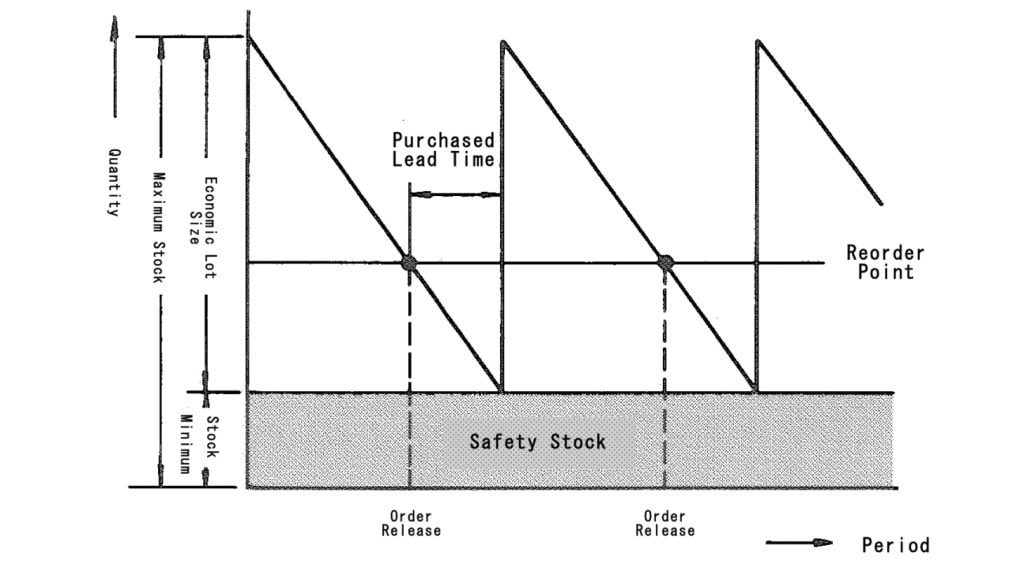

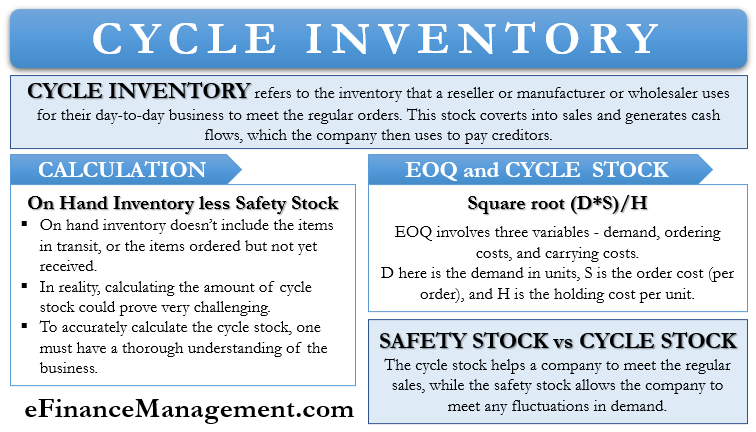

Safety stock is intended to cover any shortfall in cycle stock during the lead time period. Safety stock is a buffer- a cushion against varying lead times. Whenever demand is greater than expected or theres a delay from your supplier safety stock ensures a customer doesnt walk out the door empty-handed and disappointed.

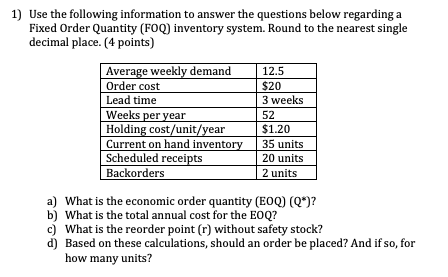

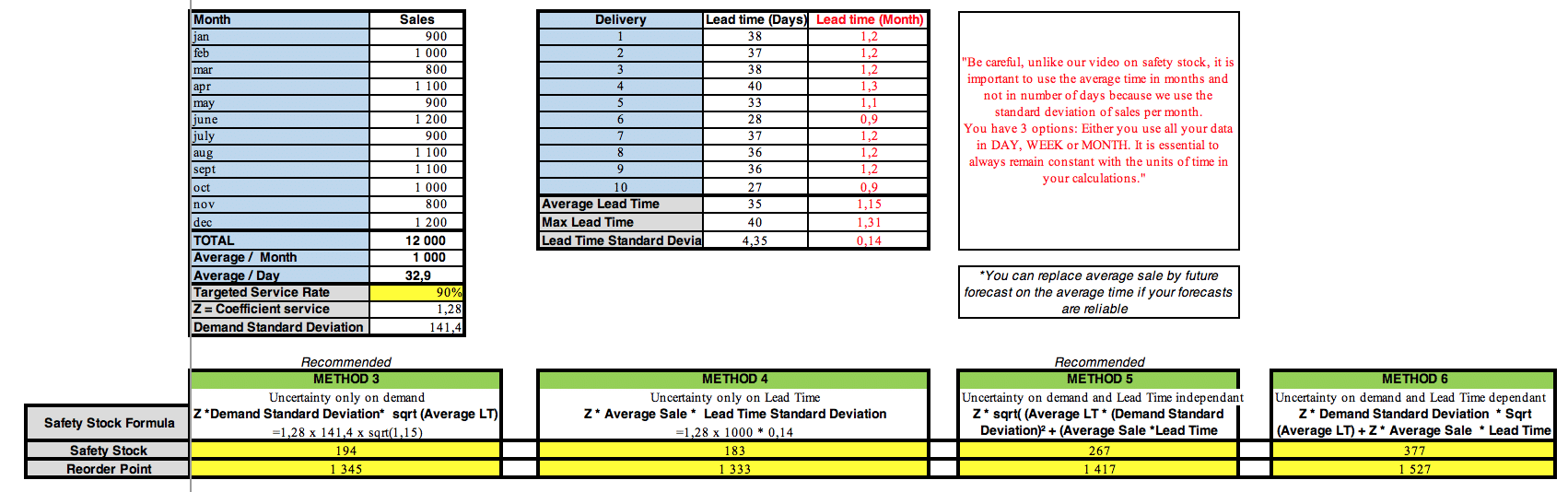

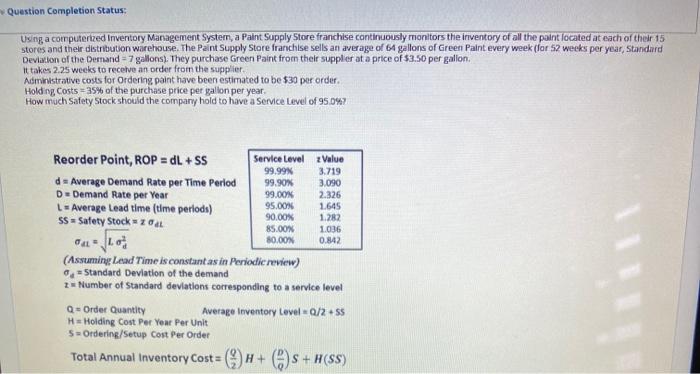

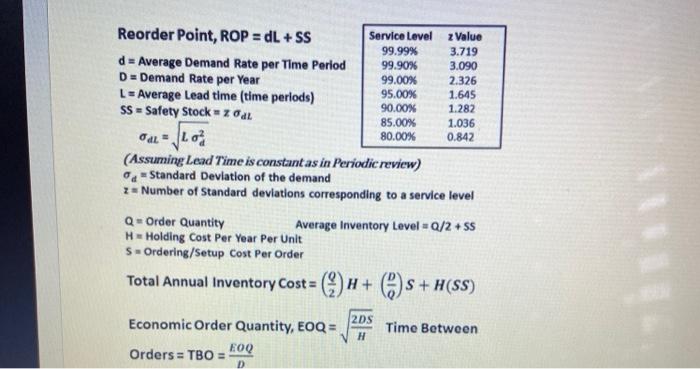

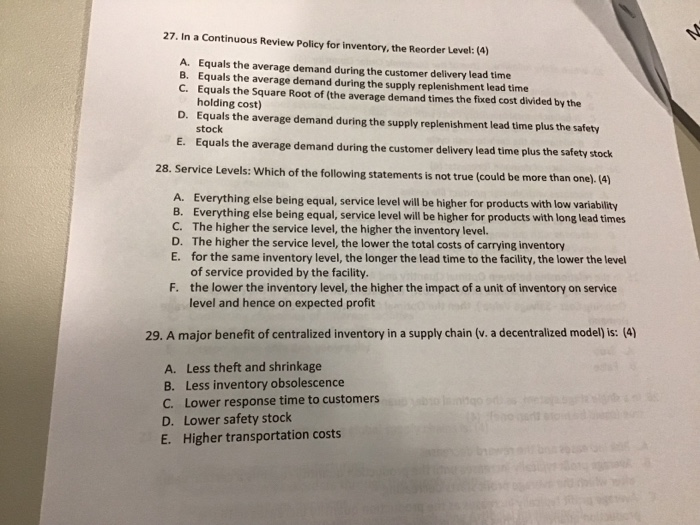

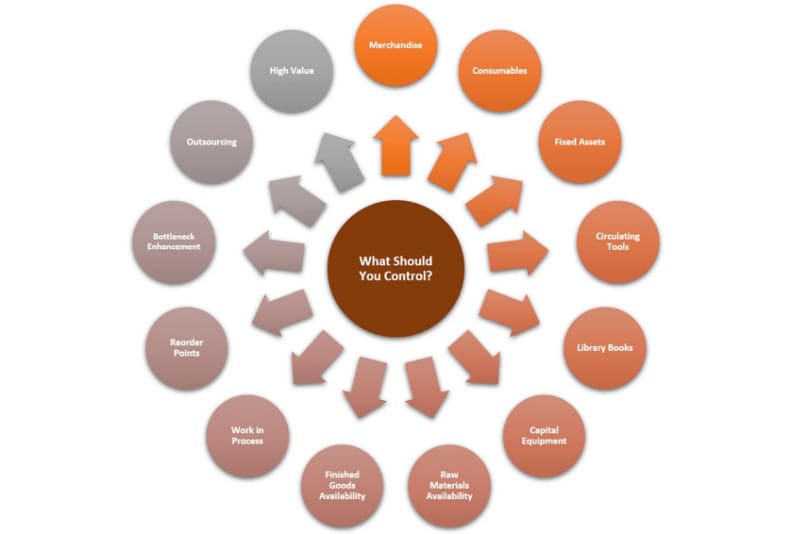

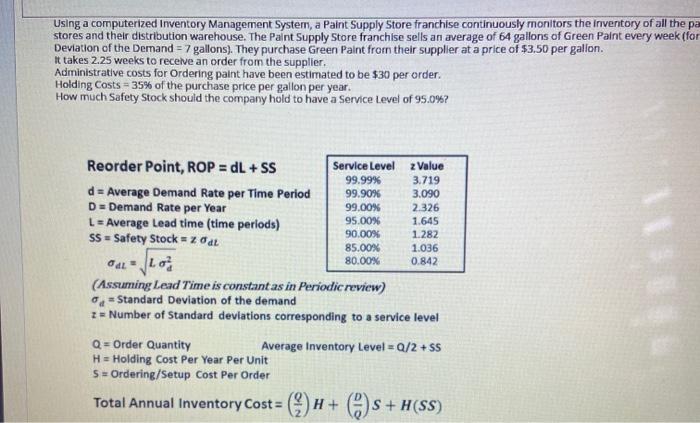

O Safety stock can be computed when using the fixed-order quantity inventory model by multiplying a z value representing the number of standard deviations to achieve a service level or probability by the standard deviation of periodic demand. Safety stock is defined as inventory that is carried to prevent stock-outs caused by fluctuating customer demand forecast inaccuracies or variability in supplier lead times. The stocks required for a fixed period of time are calculated based on the time period and are monitored periodically to ensure accuracy and fulfill the need it is intended for.

False The optimal stocking decision in inventory management when using marginal analysis occurs at the point where the benefits derived from carrying the next unit are more than the costs for that unit. The method has the following features. Safety Stock versus Safety Time optimal decision rules they could identify the amount of safety stock and safety time where they defined safety time as the time a lot spent in an intermediate store until the first item from it was used.

Safety stock is not necessary in any fixed-time period system. Safety stock is essentially the additional stock of a product you need to hold to lower your risk of a stockout.

Even relatively large fluctuations in demand can be.

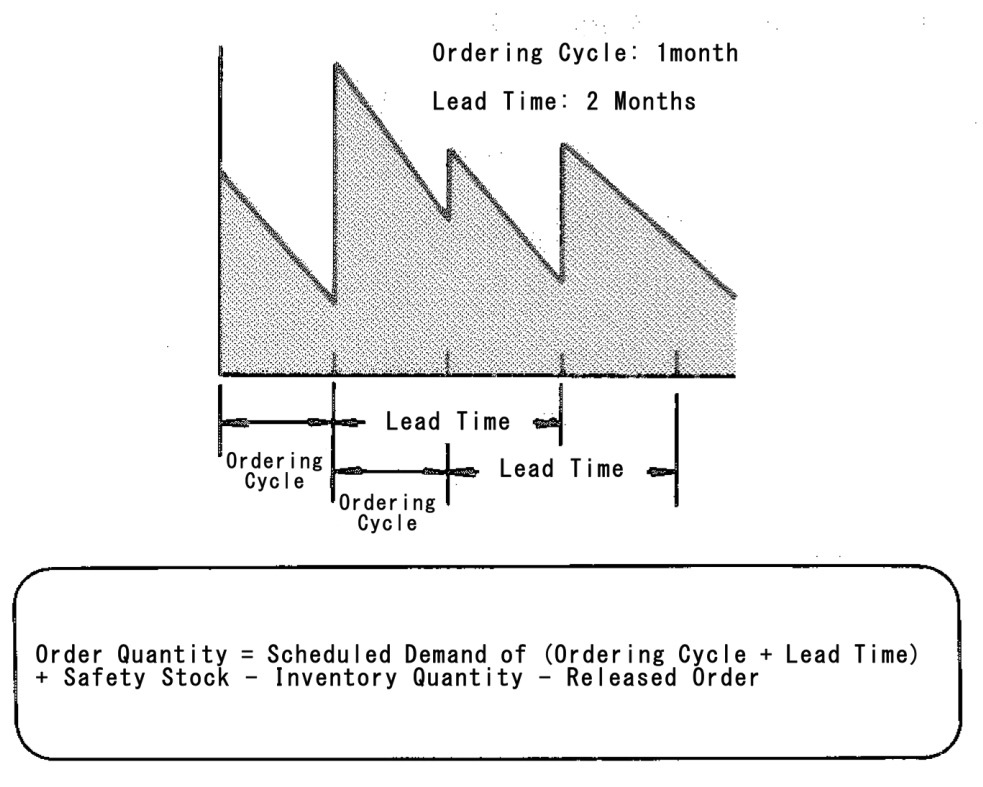

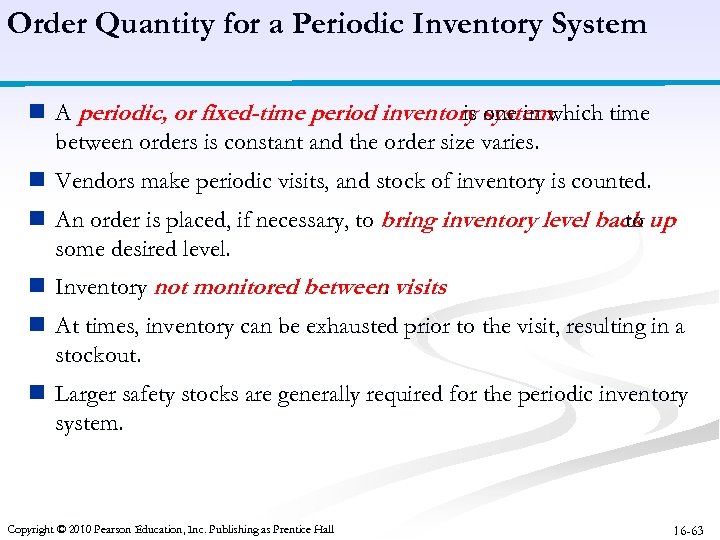

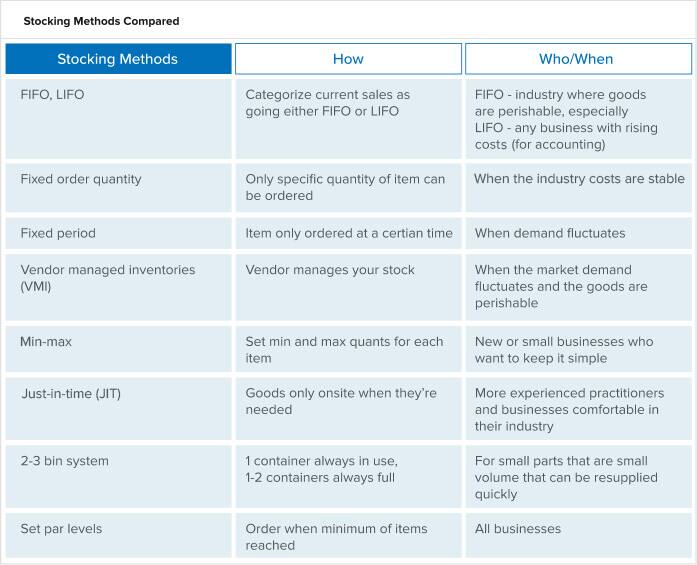

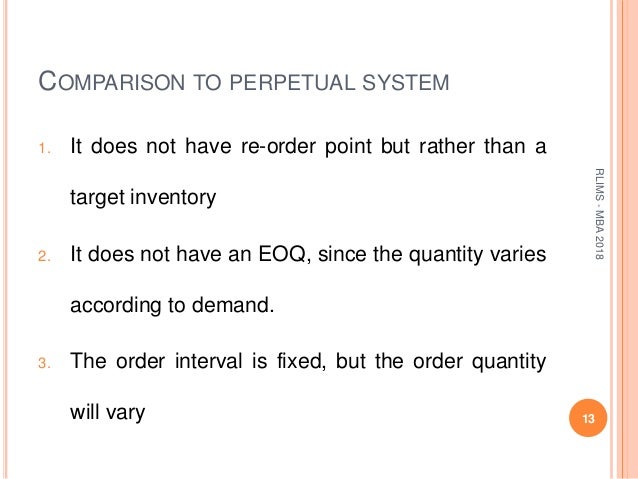

2004 offered a method based on queuing analysis to determine order-up-to levels for a R S system and a fixed cyclic production sequence where the demand is a. It is an inventory control method where orders are periodically placed but the order quantity is different every time and is also called Fixed Period Deficit Ordering System. We need to maintain the extra stock to ensure a consistent flow of business and retain our customers. Q 31 Some inventory situations involve placing orders to cover only one demand period or to cover short-lived items at frequent intervals. FALSE In the fixed-time period model it is necessary to determine the inventory currently on hand to calculate the size of the order to place with a vendor. Safety stock or buffer stock is the amount of extra inventory you need to keep avoid a shortfall of materials. Safety stock determinations are not intended to eliminate all stockoutsjust the majority of them. 2004 offered a method based on queuing analysis to determine order-up-to levels for a R S system and a fixed cyclic production sequence where the demand is a. O Safety stock can be computed when using the fixed-order quantity inventory model by multiplying a z value representing the number of standard deviations to achieve a service level or probability by the standard deviation of periodic demand.

Explore answers and other related questions 10 million students use Quizplus to study and prepare for their homework quizzes and exams through 20m questions in 300k quizzes. Answered Aug 19. Safety stock is not necessary in any fixed-time-period. An order is periodically placed. 2004 offered a method based on queuing analysis to determine order-up-to levels for a R S system and a fixed cyclic production sequence where the demand is a. Safety Stock versus Safety Time optimal decision rules they could identify the amount of safety stock and safety time where they defined safety time as the time a lot spent in an intermediate store until the first item from it was used. O Safety stock is necessary in any fixed-time period system.

Post a Comment for "Safety Stock Is Not Necessary In Any Fixed-time-period System"